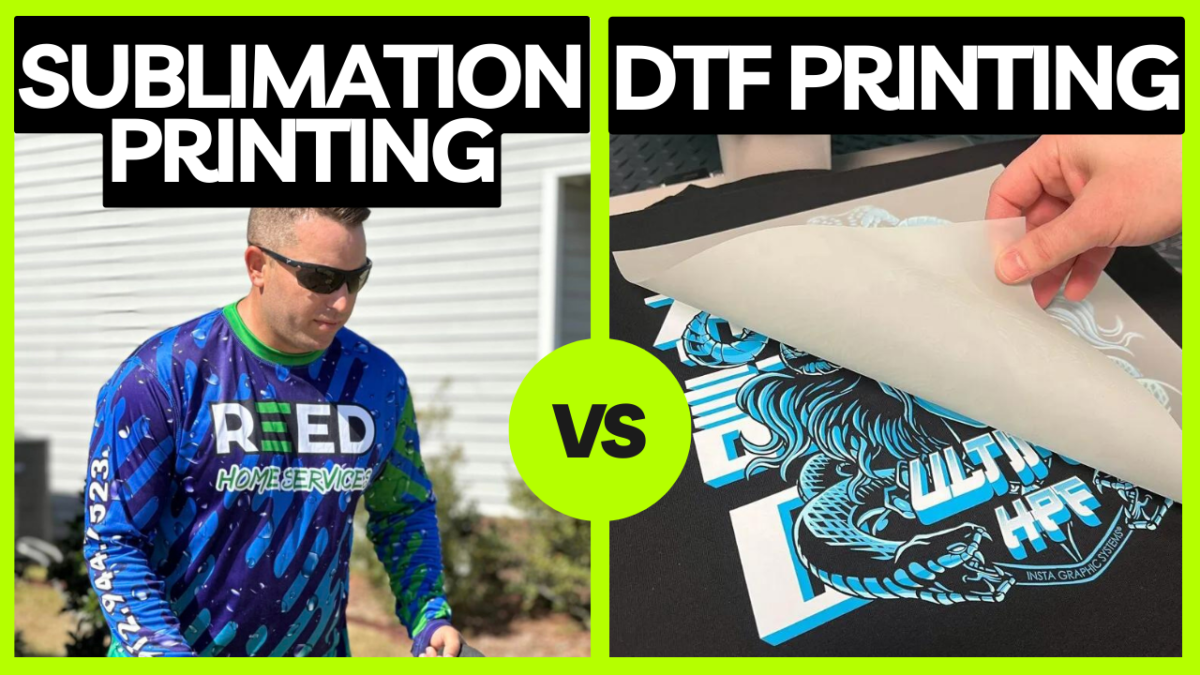

We get this question many times – Why is sublimation printing the best? Or what other type of printing do we recommend?

There are many techniques available in the market and we love working with sublimation ink, but still, if we have to choose our second favorites, then I would give my vote to DTF printing or DTG printing. With innovative printing technologies empowering entrepreneurs to customize apparel, hard goods, phone cases, etc., in affordable ways, the dilemma is real.

DTF stands for Direct to Film where we use a DTF sheet, dedicated powder, and curing technique instead of sublimation paper and ink.

Sublimation offers photorealistic full-color prints, while DTF scores high on customization for fabric printing. But which one is ideal when you are just getting started?

Don’t worry we will go into this topic in detail and give you a solid comparison of DTF vs Sublimation Printing, but first let’s discuss these technologies in brief.

How Does Sublimation Printing Work?

Sublimation printing, also known as dye-sublimation, is a printing technology that creates permanent graphics on various materials, including aluminum, wood, ceramics, synthetics, and polymer-coated products.

Sublimation inks differ from traditional inks as they have finely grounded dye particles dissolved in a liquid solution to facilitate transfer. There are different types of sublimation inks, such as:

- Dye Sublimation Ink: The standard and most common sublimation ink which contains dispersed dyes dissolved in liquid solvents like glycol or ethanol.

- Sublimation Gel Ink: Gel-based ink that provides vibrant colors.

- Water-Based Sublimation Ink: Environment-friendly, solvent-free ink which is a mix of dyes dissolved in water with glycol additives.

- Hybrid Sublimation Ink: Proprietary hybrid between solvent and water-based inks.

Benefits of Sublimation

Sublimation printing has advantages over other digital printing methods when used appropriately. Some noteworthy benefits of using the sublimation method for printing are:

- Provides high-resolution, photorealistic, and permanent colors that do not crack or fade with time or use. This makes the prints last longer without losing vibrancy.

- Ability to print all colors in full spectrum, including gradients, making photo reproductions possible.

- Unmatched customization with prints possible on a wide range of everyday products like phone covers, coffee mugs, lamps, keychains, etc.

- Requires simpler equipment like heat presses than alternatives like screen printing.

- Produces professional prints at relatively low costs suitable for small businesses.

The permanence of the colored dyes infused deep into the material, the wide color range, and the simplicity of the process make sublimation an ideal choice for entrepreneurs to build a custom merchandising business with low overheads.

How Does DTF Printing Work?

DTF printing involves transferring printed images to fabric using a heat press. It allows printing full-color graphics directly onto t-shirts, hoodies, scarves, canvas bags, and other cotton or poly-blended apparel.

DTF printing uses plastisol inks containing PVC resin that gets deposited onto a coated release paper, creating a thin film. This ink film with the printed design can then be heat-pressed onto fabrics. Plastisol inks come in both liquid and gel forms.

Before transferring the ink to any blank, you need tgo treat your film with a dedicated powder and cure it using an oven. Remember, all these inks are chemicals and you should cover your face with a regular mask, keep your windows open and turn on your exhaust fan before you start working.

Benefits of DTF Printing

The benefits of DTF Printing are:

- Prints on cotton and poly-cotton fabrics: DTF allows direct printing on t-shirts, hoodies, scarves, bags, and more.

- Soft hand feel: DTF prints are smooth compared to screen prints without feeling ‘plastic-y.’

- Vibrant, photorealistic colors: Accurately matches designs through CMYK and spot color inks.

- Lower startup costs than screen printing: Digital printers are more feasible for beginners to adopt.

- Ideal for small and customized runs: Suitable for personalized merchandising with lower volume and design flexibility.

DTF vs Sublimation Printing

While both sublimation and DTF hold great potential, understanding the core differences between DTF vs printing is crucial before finalizing the technology suitable for your use case.

Let us take a look at the key differences:

Setting Up The Machinery

For Sublimation, you just need to order an inkjet printer, convert it into a sublimation printer by replacing its original ink with sublimation ink (remember to instantly change the inks before taking out even a single print), buy some sublimation papers and you ready to go printing

With DTF, you need to unbox a bulky box of machinery, setup the same for nearly 2 hours, setup your oven, fill the cartidges with ink, prepare the nozzle and then you are ready for some printing.

In this department, Sublimation wins hands down.

Materials Required

For Sublimation, you need to have a printer, Sublimation Paper, Butcher Paper, Ink and Heatpress and the total cost can be around $500 whereas, for DTF, you need to have DTF printer, DTF film, curing powder, microwave oven and heatpress and the total cost can go upto $3000.

Print Quality

Sublimation produces more photorealistic and intricate prints, given its ability to print higher DPI (dots per inch) resolution, reaching up to 1440 dpi based on the device’s capability.

DTF prints top out at around 720 dpi resolution. But DTF also provides vibrant, accurate colors through CMYK and spot color matching.

Overall, sublimation edges out DTF when the finest details matter.

Maintenance

With Sublimation, its pretty easy. You fill in your ink tank and keep it idle for 3 months without any issue but with DTF, you need to maintain it every month by cleaning the ink head and nozzle so that it functions properly without any bleeding issue.

Customization Capabilities

One major benefit of sublimation is the wide choice of merchandise – mugs, smartphone covers, glass/metal/wood items, etc. – along with fabrics but it lacks on the kind of fabric you can use. It should be atleast 70% polyester and you cannot directly print on cotton.

with DTF, you can print on many fabrics, be it cotton or polyster or be it white or dark colored fabrics. DTF holds the edge for soft-feel fabric printing targeted at apparel and fashion accessories, allowing easy graphics.

Cost Per Print

You can get a sublimation print for as low as $0.50 and the same would go upto $1.50 for a DTF print.

Quick Comparison

| Parameter | Sublimation | DTF |

|---|---|---|

| Setup | Very Easy and Straight-forward | Complex and Time Consuming |

| Materials Requirement | Less number with easy accessibility | A bit more than Sublimation |

| Print Quality | Gives Vibrant results without any texture | Gives bright colored prints with a smooth texture |

| Maintenance | Low Maintenance | Monthly Maintenance required |

| Customization | Less Customizable | Can be used on various blanks |

| Cost per Print | $0.50 | $1.50 |

Final Thoughts

While both sublimation and DTF hold tremendous potential for on-demand printing, their inherent strengths vary based on factors like investment budgets, target products, volumes, and expertise.

When choosing between them, carefully weigh priorities around print realism, material versatility, scalability, and learning curves. For most small businesses, Sublimation provides an easier path to start fabric printing with lower risks.

Sublimation offers superior quality and customization scope with low starting cost.

Hopefully, the comparisons compiled here will help identify the benefits of each technology to pick the best-aligned solution for your goals.