If you have your sublimation printing set up, you might have gone through problems while printing your design. There could have been times when the colors were dull or smudged off, ruining your fabric.

This can all be due to the wrong heat press settings. You could make mistakes if you do not set the right temperature and time on your sublimation heat press for different printing surfaces.

So, we are here to guide you through all the facets of digital printing. Let’s delve into this topic further to learn everything about sublimation heat press settings.

What is Sublimation Printing?

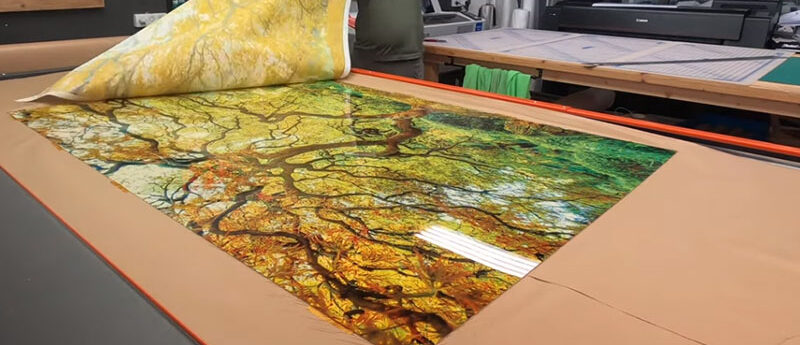

To tell you the truth, sublimation printing is not like traditional printing methods. It uses the chemical process of sublimating the ink on the surface. What it does is convert dry ink from a solid state to gas and transfer it from the sublimation paper over to the printing surface or a substrate. This process is done by putting heat and pressure over the printing surface.

For sublimation printing, you will require a sublimation printer. This printer uses sublimation ink, and the design of your choice is printed over sublimation paper. Sublimation ink and paper are important in this process as they have the properties required to achieve the best results.

As an experienced printer, here is how you go about the process: The print is placed on the substrate, and pressure and heat are applied. This usually needs a special heat press according to your substrate.

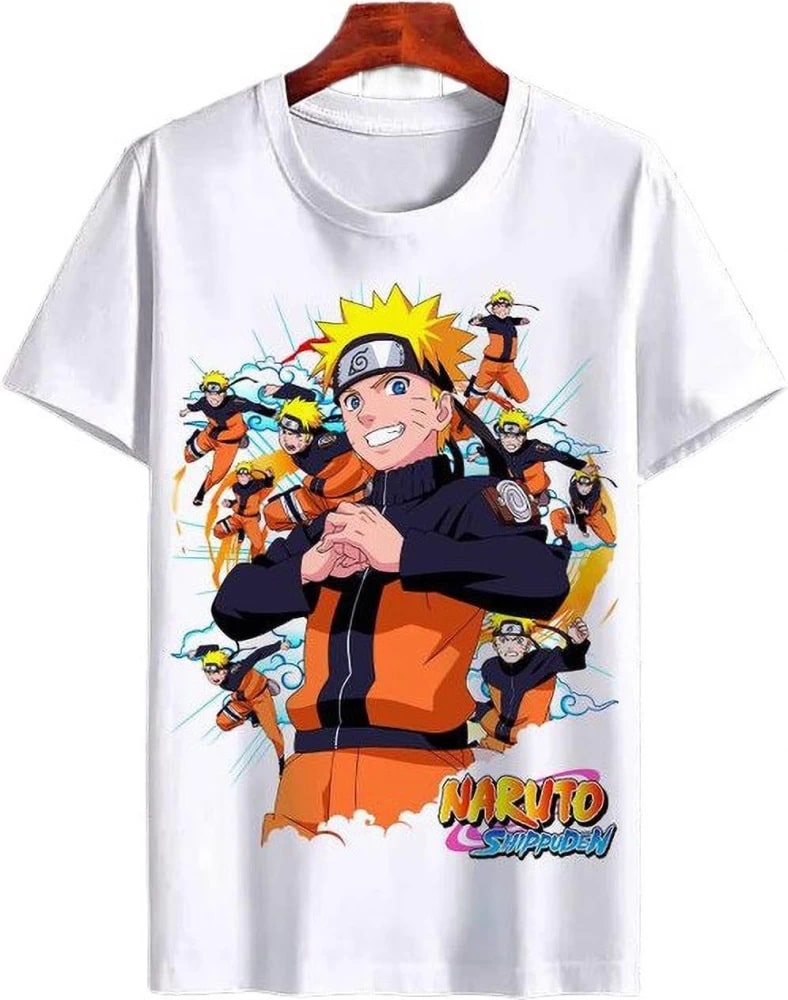

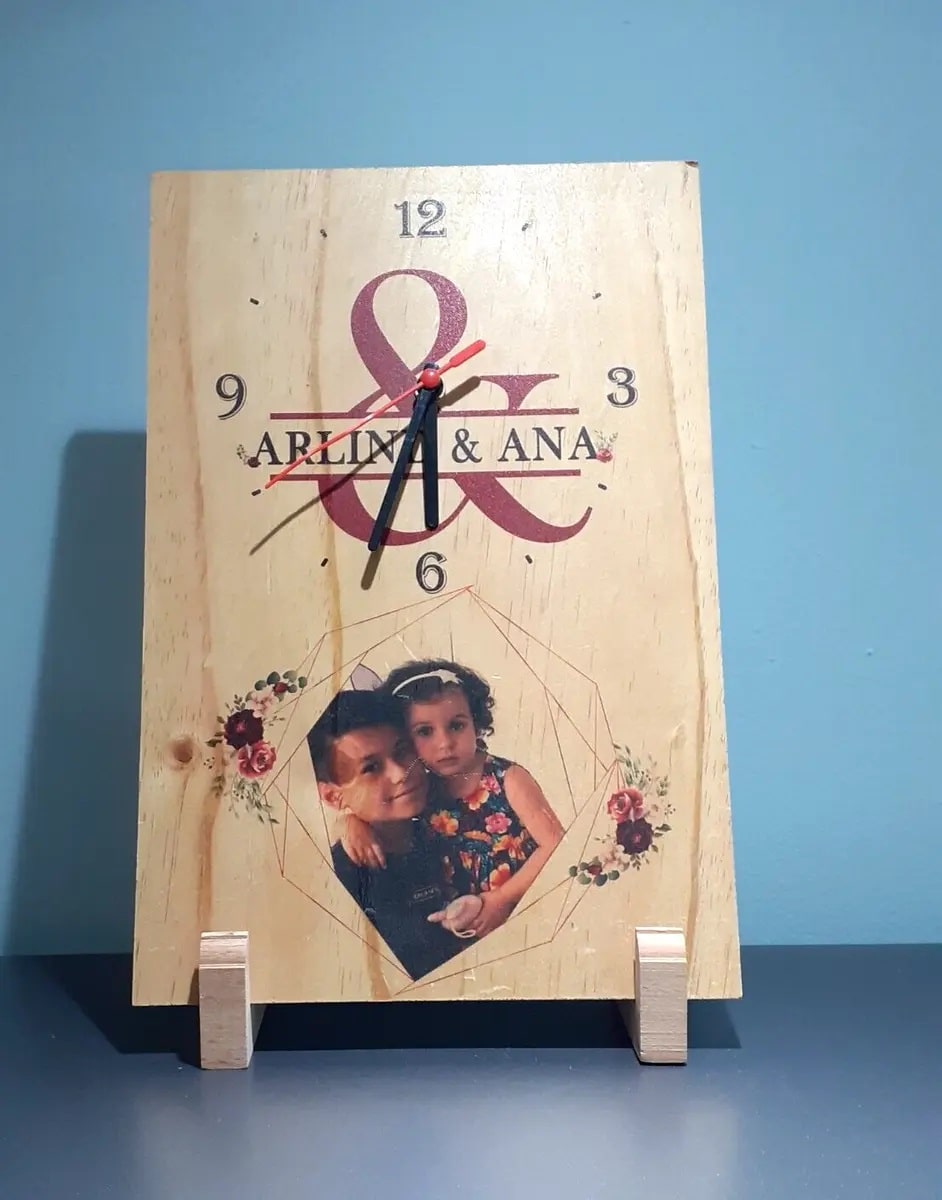

You can get the best results with sublimation printing where your substrate has 100% polyester. A polymeric surface will help the ink embed in the surface, providing an excellent finish to the product. Did you know that sublimation printing can be done on any surface like glass, wood, metal, ceramic, or fabric, as long as it has at least 70% polyester? It’s incredible, right?

Why Are Sublimation Heat Press Settings So Important?

Before diving into knowing the perfect heat press settings for your substrate, let me tell you why these settings are important. A good quality print is achieved only if the time and temperature are correct. Higher temperatures will cause a vapor pressure increase, leaving you with a poor finish or uneven spots, whereas low temperatures will give you less vibrant colors.

Durability

Your settings will define the durability of your product. The print may crack or peel off from the substrate without the perfect settings. The correct temperature will ideally let the ink bond with your substrate, reducing the chances of damage.

Better Results

If you are printing for your clients, the resulting printed product will define your reputation. It becomes important to maintain consistency while ensuring quality. The right amount of heat at the right time is necessary for better product results.

Cost Efficiency

While maintaining quality, you must also make sure that the product is cost-effective. Wrong settings will result in loss of ink or even the substrate. If you know the correct settings of the heat press for your substrate, you will be able to curb the cost and ensure profitability.

Settings for Various Surfaces

The time has come to address the issue. Given that you can do sublimation printing on a variety of surfaces, you need to choose the right settings for better results. The time to apply heat and pressure to your substrate is as important as the temperature.

We have listed below various surfaces and the required heat press settings.

Polyester

Printed fabrics are in huge demand, and polyester fabrics are considered the best substrates for sublimation. The nature of polyester to blend with the sublimation ink allows you to gain better results. The ink is embedded in the fabric, giving it a smooth finish, unlike traditional printing, which leaves a layer of print over the fabric.

We recommend you set your heat press at 400°F for 35-40 seconds at a medium pressure of about 40 psi.

Ceramic

Ceramic sublimation can require a special heat press that can accommodate the cylindrical shape of mugs and tumblers. For ceramic substrates, the recommended temperature is 350-400°F for 150-210 seconds at a pressure of 40 psi.

Metal

Sublimation on metal surfaces looks shinier than any other sublimation material. Make sure to remove the plastic coating from the metal surface before printing. Then warm up the heat press to 400°F and press the design for 60-80 seconds at a medium pressure of 40 psi.

Hardboard or MDF

A hardboard is an engineered wood product that needs less heat press time. You should keep the hardboard in the heat press for 40-80 seconds at a 360- 400°F temperature range. Keep the pressure medium (40 psi).

However, MDF sheets require more time than hardboards. Keep the MDF sheet in a heat press for around 80-90 seconds.

Plywood

The plywood needs to be cleaned before placing in the heat press. Warm up the press to 400°F and press the design for 60-70 seconds at medium pressure.

Fiberglass Reinforced Plastic

FRP requires a little less time than MDF. You must press the design for 60-75 seconds at medium pressure with a temperature of 380-400°F.

Conclusion

To wrap this up, sublimation becomes an easy printing when all the tools are used carefully. You are good to go if you know your way around the machinery. Having the necessary materials for printing is as important as knowing your heat press settings.

Heat press must be handled with care. You shall be dealing with high temperatures all the time. Some substrates can retain the heat for a longer time. Using gloves becomes important here. It is also advised to keep emergency equipment handy. Burn ointment or a small fire extinguisher are always helpful if kept nearby.

Sublimation printing is a way to let your creativity take over. You can start it as a hobby or use it to build your full-time profession. With an immense scope of work, you can use sublimation printing to design your personalized range of products. You can even freelance for any brand to print their merchandise.

So, get your heat press ready and start your printing journey.