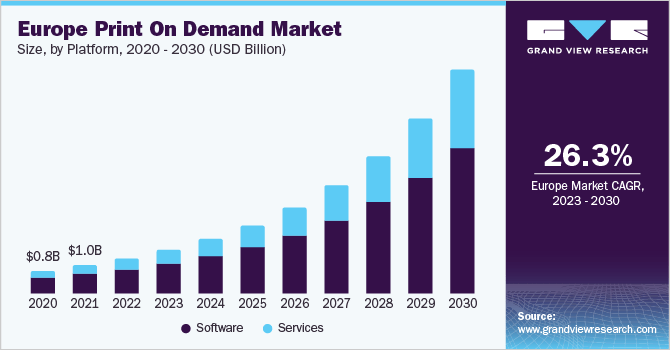

The print-on-demand industry is growing significantly. With a rise in e-commerce and small-batch printing, the print-on-demand market reached $6.18 billion in 2022. It is expected to grow at a CAGR of 25.8% till 2030. The DIY (do it yourself) trend is growing popular these days. You see people crafting objects in their style with creativity. In this comparison of sublimation vs heat transfer printing, we shall look at these methods that are taking over rapidly.

This article will guide you through various facets of printing and make it easy to decide which printing method suits you the best. So, let’s dive in and create magic!

What is Heat Transfer Printing?

In the heat transfer process, the printer applies a design to a surface using a transfer sheet. This process involves applying heat and pressure to a transfer sheet on the surface of the material so that the vinyl is transferred.

Heat transfer uses regular printer ink but requires a transfer paper to print. Once you are done printing, the design needs to be trimmed. This process is called weeding, which means removing unwanted areas and elements. Similar to sublimation, this printing style also requires a heat press.

The heat and pressure from the press activate the glue in the transfer paper, making the design stick to the surface. The paper is then peeled off.

What is Sublimation Printing?

We have covered this topic many time through our other posts, but lets give you a brief here. In this process, the design is printed on a special paper call sublimation paper and the ink used is also a sublimation ink. The paper is then attached to the blank using a heat resistant tape and after that, heat press is used to transfer the ink onto the surface.

Note: The solid ink is directly converted into gas in this process and as soon as it joins the surface at a molecular level, it is automatically converted into a solid state again. This print is long lasting and the texture is smooth.

Sublimation vs Heat Transfer Printing

It becomes important to go through the pros and cons of the printing process to decide which one suits you the best.

Here are some points for comparison between sublimation and heat transfer printing.

Startup Cost

Both methods go easy on cost for beginners. However, heat transfer can be more affordable than sublimation. This is because the special ink, paper, and printer required for sublimation increases the cost. It would be best to have a dedicated printer for sublimation printing, as you cannot mix regular ink with sublimation ink.

But there is a way out. You can convert an inkjet printer to use sublimation ink. For this, you will require the printhead to use piezoelectric instead of thermal technology. You can also use laser printers, but the cost of sublimation toners is much higher.

This brings us to heat transfer printing, which doesn’t require special ink or a special printer. All you need is transfer paper to start printing at an affordable cost.

Quality

Compared with heat transfer, sublimation printing has a smoother feel on the printing surface. The smooth finish is achieved due to the sublimation ink embedding itself into the surface fabric. This means there is no additional layering over the surface. In other words, heat transfer printing is like drawing on skin with a pen, whereas sublimation printing is like tattooing your skin.

Heat transfer printing adds a layer over the surface. You feel the change in the surface structure when touched.

Sublimation printing can be more suitable for objects or products you want to use long-term.

Durability

Sublimation printing lasts longer as it is embedded into the fabric. Sublimation printing can withstand hundreds of washes.

As heat transfer adds a layer of vinyl over the surface, it tends to fade out or crack and peel away after a few washes.

Printability

Here is a point where you might think that sublimation printing is much better than heat transfer. However, heat transfer remains popular due to many reasons.

Heat transfer printing can work on many fabrics. Sublimation, on the other hand, works only on polyester clothing and ceramics. A large percentage of the clothing market is cotton-based, which makes heat transfer printing popular.

Sublimation does not work on cotton or non-polymer surfaces as its ink requires polymeric elements to embed with.

Background Color

You can easily use heat transfer over a surface with any color. It can be printed without losing the brightness or clarity. This works because the design is first printed on a transfer sheet, which often has a white background.

The design on the transfer paper is then printed on the surface to create a layer atop the fabric. This does not allow the design to absorb any color of the printing surface.

Here are some pointers to consider:

- Background Color: You get the best results from sublimation printing using a polymeric surface with a white background. Heat transfer works best on dark background surfaces or cotton where sublimation won’t produce great results.

- Printing Surface: Sublimation printing can work well on any surface with a sublimation coating, like ceramic, glass, wood, metal, etc. This is because it does not add any layer over the surface. Heat transfer adds a layer over the surface and is prone to fading over time or developing cracks.

If you’re considering cost efficiency, durability, and printability, you should opt for heat transfer printing. However, if you are looking for good quality and an option to print on any surface material, sublimation printing is your go-to solution.

Regardless of which printing method you use, you will need a reliable heat press.